全自動鋁條折彎機在工作中有什么優勢?

時間:2025-05-16 來源:http://www.shanggu88.com/ 發布人:昌盛機械

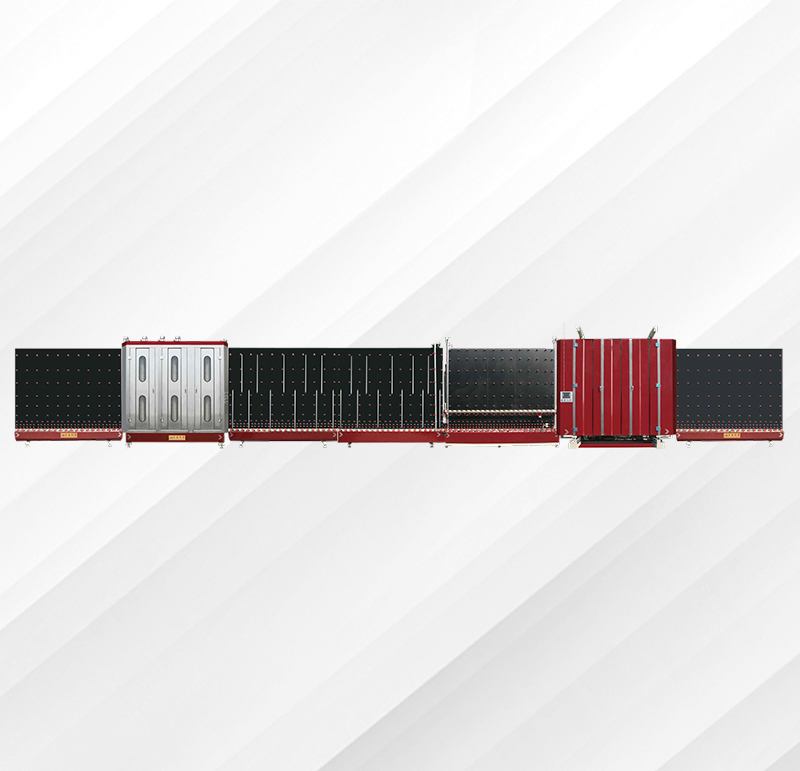

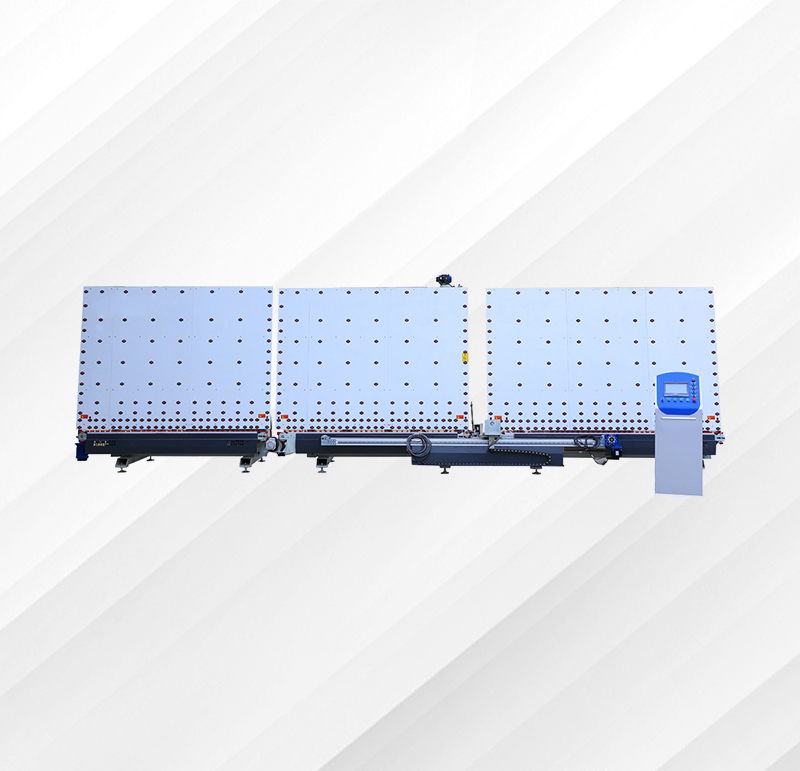

全自動鋁條折彎機是現代工業中實現鋁條精密加工的核心設備,其通過集成機械、電氣與軟件技術,將鋁條精準塑形成矩形、異型或圓弧框架。以下從機械結構、控制系統、工藝流程三大維度解析其工作原理。

The fully automatic aluminum strip bending machine is the core equipment for precision processing of aluminum strips in modern industry. It integrates mechanical, electrical, and software technologies to accurately shape aluminum strips into rectangular, irregular, or circular arc frames. The working principle is analyzed from three dimensions: mechanical structure, control system, and process flow.

一、機械結構:精密協同的物理執行系統

1、 Mechanical Structure: Precise Collaborative Physical Execution System

上料與定位模塊

Loading and positioning module

自適應傳送裝置:鋁條經上料傳送帶進入設備,兩側的轉動調節盤通過伸縮彈簧與防滑條實現自動對中。例如,當5.5-24mm寬的鋁條輸送時,傳感器實時檢測位置偏差,驅動電機帶動調節盤以±3mm的浮動范圍調整,確保鋁條居中。

Adaptive conveyor device: Aluminum bars enter the equipment through the feeding conveyor belt, and the rotating adjustment discs on both sides are automatically aligned through telescopic springs and anti slip strips. For example, when conveying aluminum bars with a width of 5.5-24mm, the sensor detects the position deviation in real time, and the driving motor drives the adjustment disc to adjust within a floating range of ± 3mm to ensure that the aluminum bars are centered.

接料機構:采用雙氣缸夾緊設計,前定位槽條與后定位槽條通過導軌滑塊實現精準對接。當鋁條尾部觸發信號時,移動氣缸以0.1mm精度推動后夾緊部件前移,完成鋁條插角U型結構的自動續接,材料利用率提升15%。

Material receiving mechanism: Adopting a dual cylinder clamping design, the front positioning groove and the rear positioning groove are precisely docked through guide rail sliders. When the tail of the aluminum strip triggers a signal, the moving cylinder pushes the rear clamping component forward with a precision of 0.1mm, completing the automatic continuation of the U-shaped structure of the aluminum strip insertion angle, and increasing material utilization by 15%.

折彎執行機構

Bending actuator

伺服驅動折彎模組:由高剛性機身、四軸伺服電機及折彎刀頭組成。以中空玻璃鋁框加工為例,刀頭角度通過諧波減速器實現0.1°分辨率調節,配合壓力傳感器實時反饋折彎力矩,確保2000×2000mm大尺寸鋁框折角誤差≤0.3mm。

Servo driven bending module: composed of a high rigidity body, a four axis servo motor, and a bending blade. Taking the processing of hollow glass aluminum frames as an example, the blade angle is adjusted to a resolution of 0.1 ° through a harmonic reducer, and real-time feedback of bending torque is provided by a pressure sensor to ensure that the bending angle error of the 2000 × 2000mm large-sized aluminum frame is ≤ 0.3mm.

img_350_220_202206061723475KC8lR.jpg

多級變速系統:根據鋁框尺寸自動調節轉速,300×300mm小框折彎速度可達120次/分鐘,而2000mm長邊則降至30次/分鐘以保障精度。

Multi speed transmission system: The speed is automatically adjusted according to the size of the aluminum frame. The bending speed of the 300 × 300mm small frame can reach 120 times/minute, while the 2000mm long side is reduced to 30 times/minute to ensure accuracy.

切割與下料裝置

Cutting and cutting device

氣動切割系統:采用雙導柱氣缸驅動鋸片,切割壓力通過比例閥精確控制。斷口處配置毛刺清理模塊,利用高速旋轉尼龍刷實現0.5mm以內的毛刺去除。

Pneumatic cutting system: The saw blade is driven by a dual column cylinder, and the cutting pressure is precisely controlled through a proportional valve. Install a burr cleaning module at the fracture site, using a high-speed rotating nylon brush to remove burrs within 0.5mm.

自動卸料機構:完成加工的鋁框經傳送帶輸送至堆垛區,配備光電傳感器檢測堆垛高度,觸發機械臂自動碼放。

Automatic unloading mechanism: The processed aluminum frame is transported to the stacking area by a conveyor belt, equipped with photoelectric sensors to detect the height of the stack and trigger the mechanical arm to automatically stack.、

二、控制系統:智能決策的神經中樞

2、 Control system: the central nervous system for intelligent decision-making

硬件架構

Hardware Architecture

主控制器:采用和利時MC1002R運動控制器,搭載ARM Cortex-A9雙核CPU,支持RTEX總線實現32軸聯動。例如,在四工位折彎機中,四組伺服軸同步誤差控制在0.05mm以內。

Main controller: Adopting the Hollysys MC1002R motion controller, equipped with ARM Cortex-A9 dual core CPU, supporting RTEX bus to achieve 32 axis linkage. For example, in a four station bending machine, the synchronization error of the four sets of servo axes is controlled within 0.05mm.

伺服系統:松下A6N系列伺服驅動器,配合23位絕對值編碼器電機,實現0.01mm的重復定位精度。

Servo system: Panasonic A6N series servo drive, combined with a 23 bit absolute encoder motor, achieves a repeat positioning accuracy of 0.01mm.

軟件算法

Software algorithm

圖形解析引擎:支持DXF、CAD等格式導入,自動生成折彎序列。例如,將正六邊形鋁框數據解析為6次折彎指令,每次旋轉60°并補償彈性回彈量。

Graphics parsing engine: supports importing formats such as DXF and CAD, and automatically generates bending sequences. For example, parsing the data of a regular hexagonal aluminum frame into 6 bending commands, rotating 60 ° each time and compensating for elastic rebound.

動態補償模塊:通過溫度傳感器監測機身熱變形,實時調整折彎參數。在連續工作8小時后,系統自動補償0.1-0.2mm的熱脹冷縮誤差。

Dynamic compensation module: monitors the thermal deformation of the body through temperature sensors and adjusts bending parameters in real time. After 8 hours of continuous operation, the system automatically compensates for thermal expansion and contraction errors of 0.1-0.2mm.

人機交互界面

Human-computer interaction interface

10.4英寸維綸觸摸屏:集成圖形化編程界面,操作人員可通過拖拽方式設定鋁框尺寸、折彎角度等參數。例如,設定300×400mm矩形框時,系統自動計算對角線誤差補償值。

10.4-inch Velon touch screen: Integrated graphical programming interface, operators can set parameters such as aluminum frame size and bending angle by dragging and dropping. For example, when setting a 300 × 400mm rectangular box, the system automatically calculates the diagonal error compensation value.

遠程診斷功能:支持以太網連接,工程師可遠程調取設備日志,通過PLC程序回放功能復現故障過程。

Remote diagnostic function: Supports Ethernet connection, engineers can remotely access device logs, and reproduce the fault process through PLC program playback function.

本文由全自動鋁條折彎機友情奉獻.更多有關的知識請點擊:http://www.shanggu88.com我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網站留言.

This article is a friendly contribution from glass coating machine equipment For more information, please click: http://www.shanggu88.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

- 解鎖異形鋁條折彎密碼:全自動折彎機操作全流程解析 2025/06/20

- 中空玻璃生產線:一塊玻璃的 “變形計” 全記錄 2025/06/18

- 中空玻璃誕生記:加工設備使用全流程大揭秘 2025/06/17

- 全自動封膠線怕腐蝕嗎?揭秘其耐久性真相與防護秘訣 2025/06/16

- 中空玻璃加工設備組成結構解析 2025/06/14

- 中空玻璃丁基膠涂布機制作流程解析 2025/06/13

- 中空玻璃加工設備怎么保障玻璃的密封性呢? 2025/06/12

- 全自動封膠線使用過程中有哪些要注意的地方? 2025/06/11

- 臥式丁基膠涂布機使用有什么需要注意的? 2025/06/10

- 玻璃涂布機設備解析:技術分類洞察 2025/06/09

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us