中空玻璃加工必備8大設備詳解

時間:2025-05-19 來源:http://www.shanggu88.com/ 發布人:昌盛機械

中空玻璃以其優異的隔熱、隔音性能,在現代建筑中占據重要地位。其加工過程需要多臺專業設備協同工作,從原片玻璃到成品中空玻璃,每道工序都離不開精密機械的支撐。以下詳解中空玻璃加工不可或缺的八大核心設備。

Hollow glass occupies an important position in modern architecture due to its excellent thermal and sound insulation properties. The processing process requires multiple professional equipment to work together, from raw glass to finished insulating glass, each process cannot do without the support of precision machinery. The following provides a detailed explanation of the eight essential core equipment for processing insulating glass.

玻璃切割設備:精準裁切的基石

Glass cutting equipment: the cornerstone of precise cutting

玻璃切割機是中空玻璃生產線的起點設備。現代數控切割機采用鉆石刀輪或激光切割技術,可根據訂單需求自動完成異形切割、打孔等復雜操作。設備配備的智能排版系統能優化原片利用率,減少邊角料浪費。對于Low-E鍍膜玻璃等特殊材質,切割機還具備除膜功能,通過機械磨削或激光蝕刻去除特定區域的鍍膜層,確保后續密封膠的粘結強度。

The glass cutting machine is the starting equipment of the insulated glass production line. Modern CNC cutting machines use diamond cutter wheels or laser cutting technology, which can automatically complete complex operations such as irregular cutting and drilling according to order requirements. The intelligent typesetting system equipped on the equipment can optimize the utilization rate of raw materials and reduce waste of scraps. For special materials such as Low-E coated glass, the cutting machine also has a film removal function, which removes the coating layer in specific areas through mechanical grinding or laser etching to ensure the bonding strength of the subsequent sealant.

磨邊倒角機組:安全與美學的雙重保障

Grinding and chamfering unit: dual guarantee of safety and aesthetics

切割后的玻璃邊緣存在微小毛刺,需經磨邊機處理。該設備采用金剛石磨輪對玻璃四邊進行精細打磨,倒角機則負責處理棱角部分。四軸聯動數控磨邊機可實現0.5-45°任意角度倒角,處理后的玻璃邊緣光滑度達到Ra0.2μm級,既消除安全隱患,又提升產品美觀度。部分機型還集成清洗功能,實現磨削、拋光、清洗一體化作業。

The edges of the cut glass have small burrs that need to be processed by a grinding machine. The equipment uses diamond grinding wheels to finely polish the four sides of the glass, while the chamfering machine is responsible for processing the sharp edges. The four axis linkage CNC edging machine can achieve chamfering at any angle of 0.5-45 °, and the smoothness of the processed glass edge reaches Ra0.2 μ m level, eliminating safety hazards and improving product aesthetics. Some models also integrate cleaning functions, achieving integrated grinding, polishing, and cleaning operations.

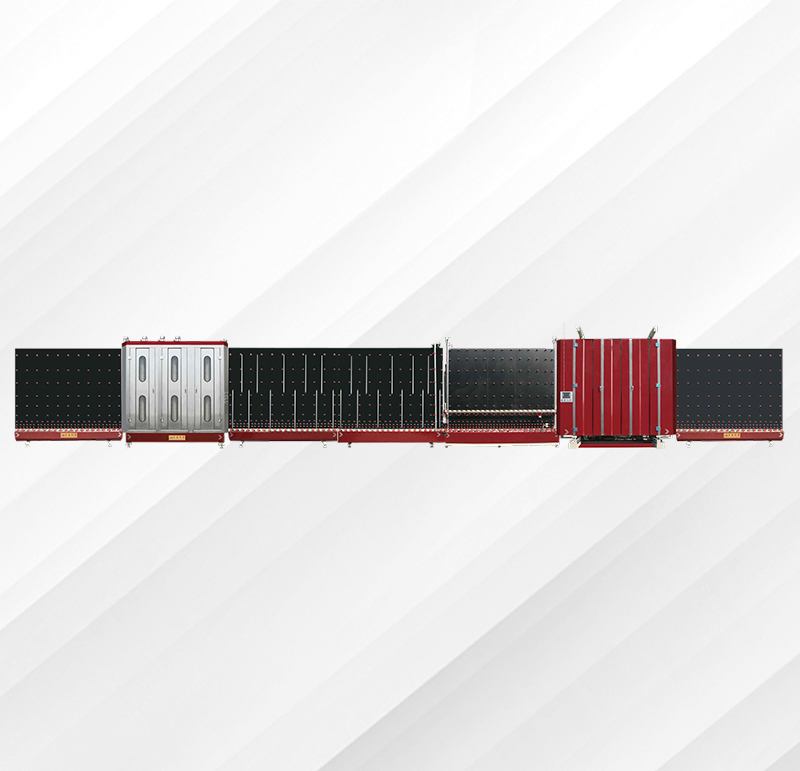

清洗干燥系統:潔凈度的守護者

Cleaning and drying system: Guardian of cleanliness

玻璃清洗機采用三段式結構設計:前段噴淋去離子水軟化污漬,中段毛刷輥深層清潔,末段高壓熱風刀干燥。設備配置雙級過濾系統,確保循環水質達到電子級潔凈標準。對于鍍膜玻璃,清洗機采用柔性尼龍刷絲,避免損傷敏感涂層。實時監測系統可檢測玻璃表面水漬殘留,自動調節風刀角度和烘干溫度,確保每片玻璃出料時達到A級潔凈標準。

The glass cleaning machine adopts a three-stage structure design: the front section sprays deionized water to soften stains, the middle section uses brush rollers for deep cleaning, and the end section uses high-pressure hot air knives for drying. The equipment is equipped with a dual stage filtration system to ensure that the circulating water quality meets electronic grade cleanliness standards. For coated glass, the cleaning machine uses flexible nylon bristles to avoid damaging sensitive coatings. The real-time monitoring system can detect residual water stains on the surface of glass, automatically adjust the angle of the air knife and drying temperature, and ensure that each piece of glass meets Class A cleanliness standards when discharged.

鋁條加工中心:框架成型的藝術家

Aluminum bar processing center: the artist of frame forming

鋁條折彎機是制作中空玻璃間隔框的關鍵設備。數控機型支持CAD圖紙直接導入,可自動完成送料、切割、90°折彎、沖孔等工序。四軸聯動系統確保復雜形狀(如梯形、弧形)的加工精度,重復定位精度達±0.1mm。配套的分子篩灌裝機采用真空吸附技術,在密閉腔體內完成干燥劑填充,避免潮氣侵入,確保分子篩活性。

Aluminum strip bending machine is a key equipment for producing insulated glass spacer frames. The CNC model supports direct import of CAD drawings and can automatically complete processes such as feeding, cutting, 90 ° bending, punching, etc. The four axis linkage system ensures the machining accuracy of complex shapes (such as trapezoids and arcs), with a repeat positioning accuracy of ± 0.1mm. The matching molecular sieve filling machine adopts vacuum adsorption technology to complete desiccant filling in a closed chamber, avoiding moisture intrusion and ensuring molecular sieve activity.

丁基膠涂布機:第一道密封的踐行者

Butyl rubber coating machine: the practitioner of the first sealing process

該設備采用精密螺桿泵送系統,將丁基熱熔膠均勻涂布在鋁間隔框兩側。涂布寬度可調范圍3-12mm,厚度控制精度達0.05mm。伺服電機驅動的鋁框輸送系統確保涂膠連續性,無斷膠、漏膠現象。部分高端機型配置紅外預熱裝置,使膠體與鋁框在60℃下預粘合,提升初粘強度。

The equipment adopts a precision screw pumping system to evenly apply butyl hot melt adhesive on both sides of the aluminum spacer frame. The coating width can be adjusted within a range of 3-12mm, and the thickness control accuracy can reach 0.05mm. The servo motor-driven aluminum frame conveyor system ensures the continuity of the coating without any breakage or leakage. Some high-end models are equipped with infrared preheating devices to pre bond the gel and aluminum frame at 60 ℃, improving the initial bonding strength.

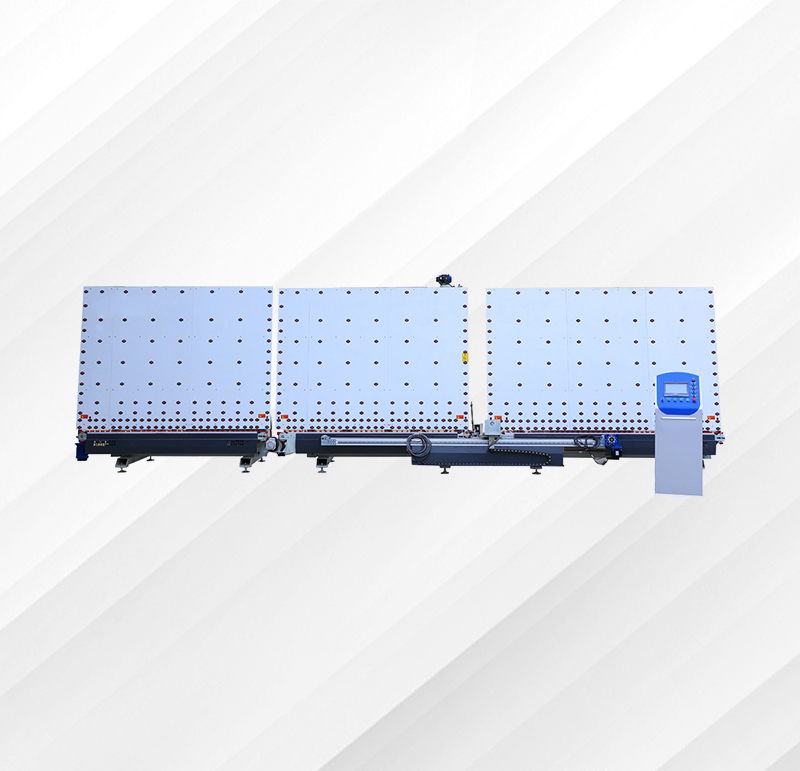

玻璃合片平臺:精密組裝的操盤手

Glass laminating platform: precision assembly operator

全自動合片機采用真空吸附技術,可同時抓取兩片玻璃進行精準對位。激光定位系統確保玻璃與鋁框的組裝精度,間隙誤差控制在±0.3mm以內。設備配置的壓力控制系統可分段施加100-500N/cm?的壓合力,確保丁基膠充分填充間隙。部分機型集成在線質量檢測功能,自動剔除對位偏差超標的產品。

The fully automatic laminating machine adopts vacuum adsorption technology, which can simultaneously grasp two pieces of glass for precise alignment. The laser positioning system ensures the assembly accuracy of the glass and aluminum frame, with a gap error controlled within ± 0.3mm. The pressure control system of the equipment configuration can apply a segmented pressure force of 100-500N/cm ? to ensure that the butyl rubber fully fills the gap. Some models integrate online quality inspection function, which automatically eliminates products with excessive alignment deviation.

雙組份打膠機:終極密封的工程師

Two component gluing machine: the ultimate sealing engineer

作為第二道密封的核心設備,雙組份打膠機采用靜態混合技術,確保A/B膠組分在噴槍內瞬間完成化學反應。設備配置的計量泵系統可精確控制混合比例,膠量輸出穩定度達±2%。仿形噴涂系統根據玻璃形狀自動規劃路徑,確保密封膠均勻覆蓋鋁框外側,膠深控制在5-7mm標準范圍。部分機型支持在線補膠功能,避免密封缺陷。

As the core equipment of the second seal, the two-component gluing machine adopts static mixing technology to ensure that the A/B glue components undergo chemical reactions instantly inside the spray gun. The metering pump system of the equipment configuration can accurately control the mixing ratio, and the stability of the adhesive output can reach ± 2%. The imitation spraying system automatically plans the path according to the shape of the glass, ensuring that the sealant evenly covers the outside of the aluminum frame, and the adhesive depth is controlled within the standard range of 5-7mm. Some models support online glue repair function to avoid sealing defects.

成品檢測系統:質量把關的守門員

Finished product inspection system: the gatekeeper of quality control

檢測線集成激光平直度儀、露點測試儀、紫外線老化箱等設備。激光掃描系統可檢測玻璃平整度,平面度誤差超過0.5mm/m自動報警。露點儀模擬極端溫濕度環境,驗證中空層密封性能。紫外線加速老化試驗確保密封膠在2000小時照射后仍保持彈性,杜絕開膠風險。

The detection line integrates equipment such as laser straightness tester, dew point tester, UV aging chamber, etc. The laser scanning system can detect the flatness of glass, and an automatic alarm will be triggered if the flatness error exceeds 0.5mm/m. The dew point meter simulates extreme temperature and humidity environments to verify the sealing performance of the hollow layer. The UV accelerated aging test ensures that the sealant maintains its elasticity even after 2000 hours of irradiation, eliminating the risk of glue cracking.

這八大設備構成完整的中空玻璃加工技術鏈,每個環節都承載著特定的技術使命。從原片處理到成品下線,設備間的數字化互聯實現生產數據實時共享,確保每片中空玻璃都達到建筑級安全標準。隨著行業對節能要求的提升,這些設備的技術迭代正推動中空玻璃向更高效、更可靠的方向發展。

These eight major equipment form a complete technology chain for hollow glass processing, with each link carrying a specific technical mission. From raw material processing to finished product production, the digital interconnection between equipment enables real-time sharing of production data, ensuring that each piece of insulated glass meets building level safety standards. With the increasing demand for energy conservation in the industry, the technological iteration of these devices is driving the development of insulating glass towards higher efficiency and reliability.

本文由中空玻璃加工設備友情奉獻.更多有關的知識請點擊:http://www.shanggu88.com我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網站留言.

This article is a friendly contribution from glass coating machine equipment For more information, please click: http://www.shanggu88.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

- 中空玻璃生產線:一條中空線至少需要幾個人? 2025/08/23

- 中空玻璃生產線的性能特點 2025/08/23

- 中空玻璃生產線安裝操作要注意什么? 2025/08/17

- 中空玻璃填充氬氣的作用 2025/08/16

- 膠條式和鋁條式中空玻璃的組裝區別 2025/08/12

- 玻璃清洗機使用過程中常見問題、注意事項及維護保養相關知識 2025/08/09

- 中空玻璃設備清洗機的維護保養工作有哪些 2025/08/09

- 中空玻璃的基本制造工藝流程是什么? 2025/08/01

- 雙組份打膠機詳解:從設計到使用維護 2025/07/30

- 雙組份打膠機:應用領域與核心優勢 2025/07/28

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us