中空玻璃生產線:一條中空線至少需要幾個人?

時間:2025-08-23 來源:http://www.shanggu88.com/ 發布人:昌盛機械

對于玻璃廠的老板和奮戰在一線的中空玻璃生產同仁們,一個核心問題始終縈繞:“我這條中空線,究竟要配多少人才能高效運轉?” 這不僅關乎人力成本,更直接影響著生產效率和訂單交付能力。今天,我們就來算算這筆“人力賬”,讓您的投入產出比更清晰!

For the owners of glass factories and the colleagues who are fighting on the front line of hollow glass production, a core question always lingers: "How many people do I need to allocate to efficiently operate my mid air line?" This not only concerns labor costs, but also directly affects production efficiency and order delivery capabilities. Today, let's calculate this' manpower account 'to make your input-output ratio clearer!

中空線核心工位與人力配置(以典型配置為例)

Core workstations and manpower configuration of Zhongkong Line (taking typical configuration as an example)

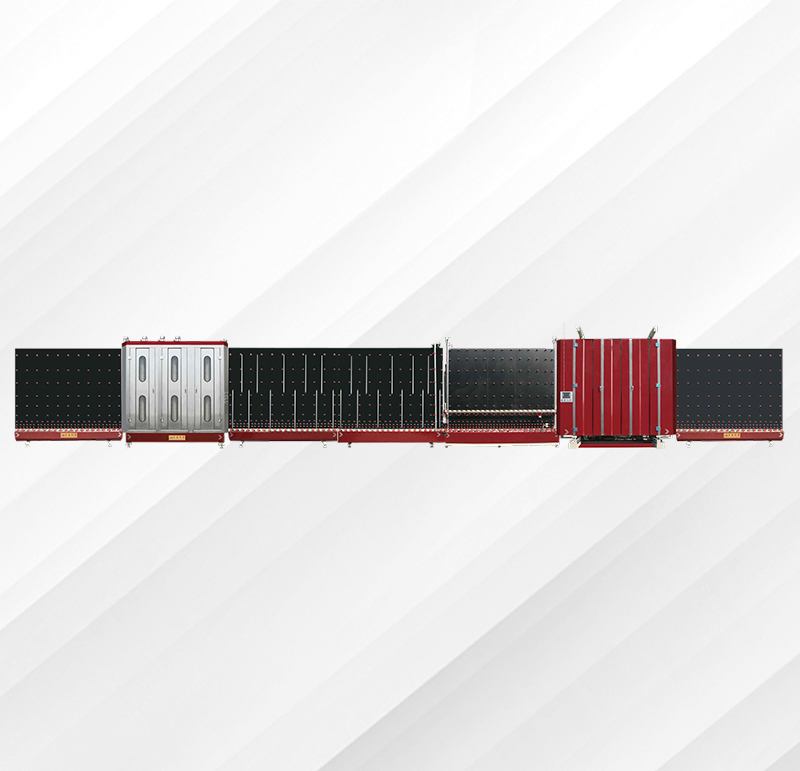

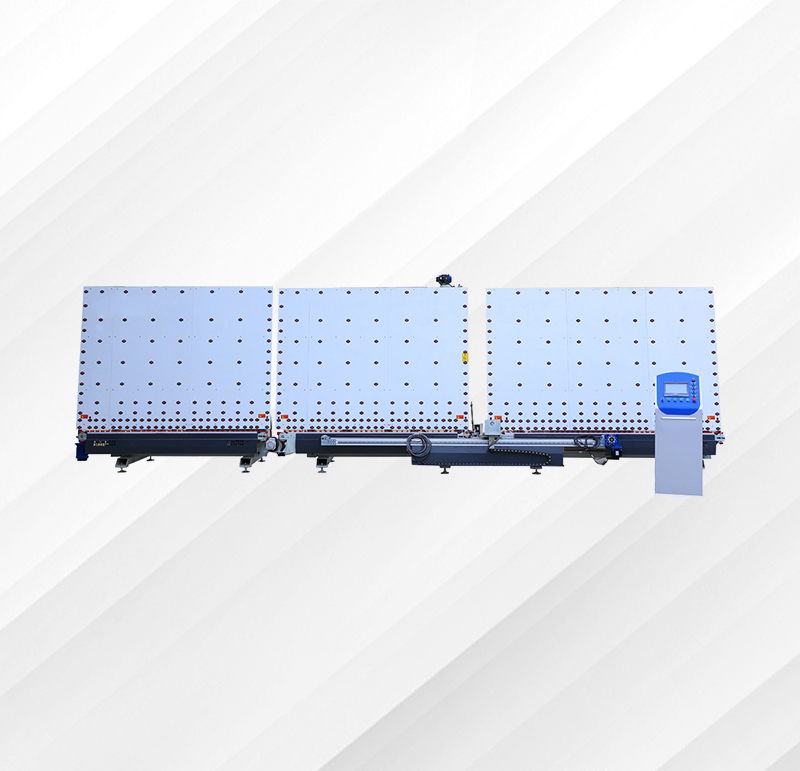

一條標準的中空玻璃生產線—上片、鋁框折彎、鋁框涂膠、上鋁框、封膠、下片等核心環節,其高效運轉需要合理分工與協作。以下是關鍵工位配置參考:

A standard insulated glass production line requires reasonable division of labor and cooperation for efficient operation, including core processes such as upper sheet, aluminum frame bending, aluminum frame coating, upper aluminum frame, sealing, and lower sheet. The following are key workstation configuration references:

01

01

關鍵工位配置參考

Reference for Key Workstation Configuration

上片工位(1人)

Loading station (1 person)

負責原片玻璃的搬運、定位、放入上片臺。勞動強度較大。

Responsible for the transportation, positioning, and placement of raw glass on the loading platform. The labor intensity is relatively high.

職責:操作上片臺/架,搬運、定位、送入原片玻璃。勞動強度大,效率直接影響整線啟動速度。

Responsibilities: Operate the loading platform/rack, transport, position, and feed the original glass sheets. The high labor intensity and efficiency directly affect the starting speed of the entire line.

人力需求:1-2人

Human resource requirement: 1-2 people

若玻璃尺寸大、重量大或上片頻繁,可能需要2人協作,

If the glass size is large, the weight is heavy, or the mounting is frequent, it may require two people to collaborate,

若工廠配置輔助吸盤,可1人完成。

If the factory is equipped with auxiliary suction cups, it can be completed by one person.

鋁框折彎及分子篩填充:1人

Aluminum frame bending and molecular sieve filling: 1 person

職責

Responsibilities

操作折彎機,根據訂單尺寸要求,對鋁間隔條進行精確折彎、插角。要求:熟練度和細心,確保角度精準、尺寸無誤。訂單切換頻繁時,效率易成瓶頸。

Operate the bending machine to accurately bend and insert the aluminum spacer according to the size requirements of the order. Requirement: Proficiency and attention to detail, ensuring precise angles and accurate dimensions. When orders switch frequently, efficiency can easily become a bottleneck.

人力需求

Human resource demand

自動化程度高或生產節奏慢時需要 1人;

When the degree of automation is high or the production pace is slow, one person is required;

生產節奏快或復雜結構多時效率更高需要2人

When the production pace is fast or the structure is complex, the efficiency is higher and requires 2 people

鋁框涂膠、上鋁框及缺陷檢查 :1人

Aluminum frame gluing, aluminum frame installation and defect inspection: 1 person

鋁框涂膠職責

Responsibilities of Aluminum Frame Coating

操作丁基膠涂布機,在折彎好的鋁框上均勻涂布第一道密封膠(丁基膠)。要求涂布連續、飽滿、無斷膠。膠溫、手法影響密封質量。

Operate the butyl rubber coating machine and evenly apply the first layer of sealant (butyl rubber) on the bent aluminum frame. Require continuous, full, and uninterrupted coating. The glue temperature and technique affect the sealing quality.

檢查上框職責

Check the responsibilities of the upper box

將涂好丁基膠的鋁框精準放置在第一片玻璃上,還需要專注檢查玻璃表面質量,此環節對位精度要求極高,尤其是三玻兩腔,直接影響兩個腔體鋁條的平整度,進而影響產品的美觀及密封質量。需細致操作,避免錯位、漏氣。

Accurately place the aluminum frame coated with butyl rubber on the first piece of glass, and focus on checking the surface quality of the glass. This process requires extremely high alignment accuracy, especially for the three glass and two cavity, which directly affects the flatness of the aluminum strips in the two cavities, thereby affecting the appearance and sealing quality of the product. Careful operation is required to avoid misalignment and air leakage.

人力需求

Human resource demand

普通生產線需要1人。

A regular production line requires one person.

大玻璃時需要增加至2個人。

When it comes to large glass, it is necessary to increase the number of people to 2.

對玻璃品質要求高,為了提高效率,也需要多人配合檢查玻璃缺陷。

High quality glass is required, and in order to improve efficiency, multiple people are needed to cooperate in inspecting glass defects.

增加玻璃缺陷檢測設備可減少1人。(這是您優化人力的核心環節!)

Adding glass defect detection equipment can reduce one person. (This is the core process of optimizing your workforce!)

二道密封膠+下片:1人

Two layers of sealant+lower piece: 1 person

封膠職責

Sealing responsibilities

在合片后的中空玻璃四周涂布第二道密封膠。這是保證長期密封性的關鍵工序。

Apply a second layer of sealant around the hollow glass after lamination. This is a key process to ensure long-term sealing.

下片職責

Responsibilities for the next film

將完成封膠的中空玻璃小心移下生產線,搬運至養護區或堆垛區。易造成邊角磕碰,勞動強度大,效率受玻璃尺寸重量影響顯著。

Carefully remove the sealed insulated glass from the production line and transport it to the curing or stacking area. Easy to cause corner collisions, high labor intensity, and efficiency significantly affected by the size and weight of the glass.

人力需求

Human resource demand

現代打膠機高度自動化,單人操作即可兼顧生產與質量監控。配合吸盤或全自動下片機,大幅節省人力,提升效率!

Modern glue machines are highly automated, allowing for single person operation to balance production and quality monitoring. Combined with suction cups or fully automatic cutting machines, it greatly saves manpower and improves efficiency!

02

02

綜合人力需求:4人

Comprehensive manpower demand: 4 people

綜合人力需求:4人一條線。不包含質檢、設備維護等輔助人員。

Comprehensive manpower demand: 4 people per line. Excluding auxiliary personnel such as quality inspection and equipment maintenance.

基礎高效配置:4 人,常見于自動化程度中等、管理優化、員工技能熟練的工廠。

Basic efficient configuration: 4 people, commonly found in factories with moderate automation, optimized management, and skilled employees.

例如:上片1人 + 鋁框折彎及分子篩填充1人 + 鋁框涂膠 /上鋁框及缺陷檢查1人 + 封膠/下片/搬運1人 (部分崗位可適度兼顧)。

For example: 1 person for loading the film+1 person for aluminum frame bending and molecular sieve filling+1 person for aluminum frame gluing/loading aluminum frame and defect inspection+1 person for sealing/unloading/handling (some positions can be moderately balanced).

傳統或復雜配置: 4 - 8人甚至更多。 多見于自動化程度低、依賴手動操作、生產超大或特種玻璃、或管理粗放的工廠。

Traditional or complex configuration: 4-8 people or even more. Commonly seen in factories with low automation, reliance on manual operation, production of oversized or special glass, or extensive management.

03

03

影響人力配置的關鍵因素

Key factors affecting human resource allocation

設備自動化水平

Equipment automation level

01

01

高品質高效率的打膠機, 自動上片臺、自動缺陷檢測機、自動合片機、機械臂的應用也能大幅降低人力需求。

The application of high-quality and efficient gluing machines, automatic loading tables, automatic defect detection machines, automatic laminating machines, and robotic arms can also significantly reduce labor requirements.

生產規模與節奏

Production scale and pace

02

02

訂單量大、生產線需要長時間連續運行時,需考慮輪班人員配置。綠色制造技術:踐行低碳發展理念

When the order volume is large and the production line needs to operate continuously for a long time, it is necessary to consider the allocation of shift personnel. Green Manufacturing Technology: Practicing the Concept of Low Carbon Development

產品復雜程度

Product complexity

03

03

生產標準矩形玻璃或者頻繁生產異形、超大、三玻兩腔、充氬氣等復雜產品,所需人力不同。

The production of standard rectangular glass or frequent production of complex products such as irregular, oversized, three glass two cavity, argon filled, etc. requires different manpower.

員工技能水平

Employee skill level

04

04

技能全面、熟練的員工可以“一人多崗”,優化配置。

Employees with comprehensive and proficient skills can work in multiple positions, optimizing their allocation.

了解一條中空玻璃生產線所需的人員數量,需要綜合考慮生產線的配置方案、自動化程度、產品復雜度以及工人技能水平等多方面因素。

To understand the number of personnel required for a hollow glass production line, it is necessary to comprehensively consider various factors such as the configuration plan, automation level, product complexity, and worker skill level of the production line.

玻璃廠老板和員工們可以根據自身企業的實際情況,合理規劃人力配置,以實現生產效率和成本控制的最佳平衡。選擇像上海星之藍這樣性能卓越、操作簡便的設備,能在一定程度上優化人力配置,提升生產效益。

Glass factory owners and employees can plan their manpower allocation reasonably based on the actual situation of their own enterprises, in order to achieve the best balance between production efficiency and cost control. Choosing equipment with excellent performance and easy operation like Shanghai Star Blue can optimize manpower allocation to a certain extent and improve production efficiency.

希望今天的分享能對大家有所幫助,如有任何關于中空玻璃生產的問題,歡迎隨時與我們交流。

I hope today's sharing can be helpful to everyone. If you have any questions about the production of insulating glass, please feel free to communicate with us at any time.

對于玻璃廠的老板和奮戰在一線的中空玻璃生產同仁們,一個核心問題始終縈繞:“我這條中空線,究竟要配多少人才能高效運轉?” 這不僅關乎人力成本,更直接影響著生產效率和訂單交付能力。今天,我們就來算算這筆“人力賬”,讓您的投入產出比更清晰!

For the owners of glass factories and the colleagues who are fighting on the front line of hollow glass production, a core question always lingers: "How many people do I need to allocate to efficiently operate my mid air line?" This not only concerns labor costs, but also directly affects production efficiency and order delivery capabilities. Today, let's calculate this' manpower account 'to make your input-output ratio clearer!

中空線核心工位與人力配置(以典型配置為例)

Core workstations and manpower configuration of Zhongkong Line (taking typical configuration as an example)

一條標準的中空玻璃生產線—上片、鋁框折彎、鋁框涂膠、上鋁框、封膠、下片等核心環節,其高效運轉需要合理分工與協作。以下是關鍵工位配置參考:

A standard insulated glass production line requires reasonable division of labor and cooperation for efficient operation, including core processes such as upper sheet, aluminum frame bending, aluminum frame coating, upper aluminum frame, sealing, and lower sheet. The following are key workstation configuration references:

01

01

關鍵工位配置參考

Reference for Key Workstation Configuration

上片工位(1人)

Loading station (1 person)

負責原片玻璃的搬運、定位、放入上片臺。勞動強度較大。

Responsible for the transportation, positioning, and placement of raw glass on the loading platform. The labor intensity is relatively high.

職責:操作上片臺/架,搬運、定位、送入原片玻璃。勞動強度大,效率直接影響整線啟動速度。

Responsibilities: Operate the loading platform/rack, transport, position, and feed the original glass sheets. The high labor intensity and efficiency directly affect the starting speed of the entire line.

人力需求:1-2人

Human resource requirement: 1-2 people

若玻璃尺寸大、重量大或上片頻繁,可能需要2人協作,

If the glass size is large, the weight is heavy, or the mounting is frequent, it may require two people to collaborate,

若工廠配置輔助吸盤,可1人完成。

If the factory is equipped with auxiliary suction cups, it can be completed by one person.

鋁框折彎及分子篩填充:1人

Aluminum frame bending and molecular sieve filling: 1 person

職責

Responsibilities

操作折彎機,根據訂單尺寸要求,對鋁間隔條進行精確折彎、插角。要求:熟練度和細心,確保角度精準、尺寸無誤。訂單切換頻繁時,效率易成瓶頸。

Operate the bending machine to accurately bend and insert the aluminum spacer according to the size requirements of the order. Requirement: Proficiency and attention to detail, ensuring precise angles and accurate dimensions. When orders switch frequently, efficiency can easily become a bottleneck.

人力需求

Human resource demand

自動化程度高或生產節奏慢時需要 1人;

When the degree of automation is high or the production pace is slow, one person is required;

生產節奏快或復雜結構多時效率更高需要2人

When the production pace is fast or the structure is complex, the efficiency is higher and requires 2 people

鋁框涂膠、上鋁框及缺陷檢查 :1人

Aluminum frame gluing, aluminum frame installation and defect inspection: 1 person

鋁框涂膠職責

Responsibilities of Aluminum Frame Coating

操作丁基膠涂布機,在折彎好的鋁框上均勻涂布第一道密封膠(丁基膠)。要求涂布連續、飽滿、無斷膠。膠溫、手法影響密封質量。

Operate the butyl rubber coating machine and evenly apply the first layer of sealant (butyl rubber) on the bent aluminum frame. Require continuous, full, and uninterrupted coating. The glue temperature and technique affect the sealing quality.

檢查上框職責

Check the responsibilities of the upper box

將涂好丁基膠的鋁框精準放置在第一片玻璃上,還需要專注檢查玻璃表面質量,此環節對位精度要求極高,尤其是三玻兩腔,直接影響兩個腔體鋁條的平整度,進而影響產品的美觀及密封質量。需細致操作,避免錯位、漏氣。

Accurately place the aluminum frame coated with butyl rubber on the first piece of glass, and focus on checking the surface quality of the glass. This process requires extremely high alignment accuracy, especially for the three glass and two cavity, which directly affects the flatness of the aluminum strips in the two cavities, thereby affecting the appearance and sealing quality of the product. Careful operation is required to avoid misalignment and air leakage.

人力需求

Human resource demand

普通生產線需要1人。

A regular production line requires one person.

大玻璃時需要增加至2個人。

When it comes to large glass, it is necessary to increase the number of people to 2.

對玻璃品質要求高,為了提高效率,也需要多人配合檢查玻璃缺陷。

High quality glass is required, and in order to improve efficiency, multiple people are needed to cooperate in inspecting glass defects.

增加玻璃缺陷檢測設備可減少1人。(這是您優化人力的核心環節!)

Adding glass defect detection equipment can reduce one person. (This is the core process of optimizing your workforce!)

二道密封膠+下片:1人

Two layers of sealant+lower piece: 1 person

封膠職責

Sealing responsibilities

在合片后的中空玻璃四周涂布第二道密封膠。這是保證長期密封性的關鍵工序。

Apply a second layer of sealant around the hollow glass after lamination. This is a key process to ensure long-term sealing.

下片職責

Responsibilities for the next film

將完成封膠的中空玻璃小心移下生產線,搬運至養護區或堆垛區。易造成邊角磕碰,勞動強度大,效率受玻璃尺寸重量影響顯著。

Carefully remove the sealed insulated glass from the production line and transport it to the curing or stacking area. Easy to cause corner collisions, high labor intensity, and efficiency significantly affected by the size and weight of the glass.

人力需求

Human resource demand

現代打膠機高度自動化,單人操作即可兼顧生產與質量監控。配合吸盤或全自動下片機,大幅節省人力,提升效率!

Modern glue machines are highly automated, allowing for single person operation to balance production and quality monitoring. Combined with suction cups or fully automatic cutting machines, it greatly saves manpower and improves efficiency!

02

02

綜合人力需求:4人

Comprehensive manpower demand: 4 people

綜合人力需求:4人一條線。不包含質檢、設備維護等輔助人員。

Comprehensive manpower demand: 4 people per line. Excluding auxiliary personnel such as quality inspection and equipment maintenance.

基礎高效配置:4 人,常見于自動化程度中等、管理優化、員工技能熟練的工廠。

Basic efficient configuration: 4 people, commonly found in factories with moderate automation, optimized management, and skilled employees.

例如:上片1人 + 鋁框折彎及分子篩填充1人 + 鋁框涂膠 /上鋁框及缺陷檢查1人 + 封膠/下片/搬運1人 (部分崗位可適度兼顧)。

For example: 1 person for loading the film+1 person for aluminum frame bending and molecular sieve filling+1 person for aluminum frame gluing/loading aluminum frame and defect inspection+1 person for sealing/unloading/handling (some positions can be moderately balanced).

傳統或復雜配置: 4 - 8人甚至更多。 多見于自動化程度低、依賴手動操作、生產超大或特種玻璃、或管理粗放的工廠。

Traditional or complex configuration: 4-8 people or even more. Commonly seen in factories with low automation, reliance on manual operation, production of oversized or special glass, or extensive management.

03

03

影響人力配置的關鍵因素

Key factors affecting human resource allocation

設備自動化水平

Equipment automation level

01

01

高品質高效率的打膠機, 自動上片臺、自動缺陷檢測機、自動合片機、機械臂的應用也能大幅降低人力需求。

The application of high-quality and efficient gluing machines, automatic loading tables, automatic defect detection machines, automatic laminating machines, and robotic arms can also significantly reduce labor requirements.

生產規模與節奏

Production scale and pace

02

02

訂單量大、生產線需要長時間連續運行時,需考慮輪班人員配置。綠色制造技術:踐行低碳發展理念

When the order volume is large and the production line needs to operate continuously for a long time, it is necessary to consider the allocation of shift personnel. Green Manufacturing Technology: Practicing the Concept of Low Carbon Development

產品復雜程度

Product complexity

03

03

生產標準矩形玻璃或者頻繁生產異形、超大、三玻兩腔、充氬氣等復雜產品,所需人力不同。

The production of standard rectangular glass or frequent production of complex products such as irregular, oversized, three glass two cavity, argon filled, etc. requires different manpower.

員工技能水平

Employee skill level

04

04

技能全面、熟練的員工可以“一人多崗”,優化配置。

Employees with comprehensive and proficient skills can work in multiple positions, optimizing their allocation.

了解一條中空玻璃生產線所需的人員數量,需要綜合考慮生產線的配置方案、自動化程度、產品復雜度以及工人技能水平等多方面因素。

To understand the number of personnel required for a hollow glass production line, it is necessary to comprehensively consider multiple factors such as the configuration plan, automation level, product complexity, and worker skill level of the production line.

玻璃廠老板和員工們可以根據自身企業的實際情況,合理規劃人力配置,以實現生產效率和成本控制的最佳平衡。選擇像上海星之藍這樣性能卓越、操作簡便的設備,能在一定程度上優化人力配置,提升生產效益。

Glass factory owners and employees can plan their manpower allocation reasonably based on the actual situation of their own enterprises, in order to achieve the best balance between production efficiency and cost control. Choosing equipment with excellent performance and easy operation like Shanghai Star Blue can optimize manpower allocation to a certain extent and improve production efficiency.

希望今天的分享能對大家有所幫助,如有任何關于中空玻璃生產的問題,歡迎隨時與我們交流。

I hope today's sharing can be helpful to everyone. If you have any questions about the production of insulating glass, please feel free to communicate with us at any time.

本文由 中空玻璃生產線 友情奉獻.更多有關的知識請點擊 http://www.shanggu88.com/ 真誠的態度.為您提供為全面的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from the insulating glass production line For more related knowledge, please click http://www.shanggu88.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

- 中空玻璃生產線:一條中空線至少需要幾個人? 2025/08/23

- 中空玻璃生產線的性能特點 2025/08/23

- 中空玻璃生產線安裝操作要注意什么? 2025/08/17

- 中空玻璃填充氬氣的作用 2025/08/16

- 膠條式和鋁條式中空玻璃的組裝區別 2025/08/12

- 玻璃清洗機使用過程中常見問題、注意事項及維護保養相關知識 2025/08/09

- 中空玻璃設備清洗機的維護保養工作有哪些 2025/08/09

- 中空玻璃的基本制造工藝流程是什么? 2025/08/01

- 雙組份打膠機詳解:從設計到使用維護 2025/07/30

- 雙組份打膠機:應用領域與核心優勢 2025/07/28

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us