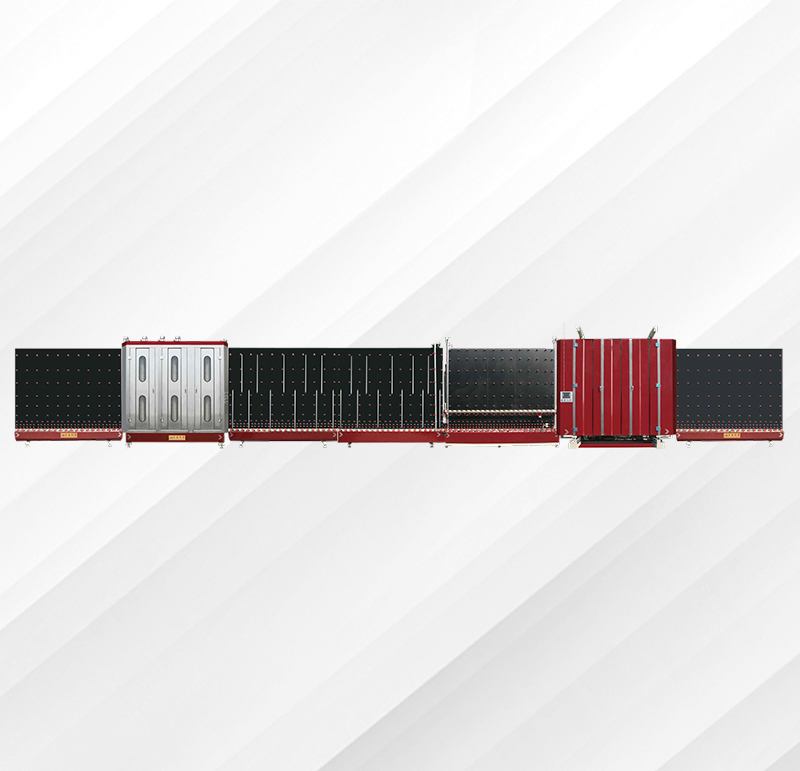

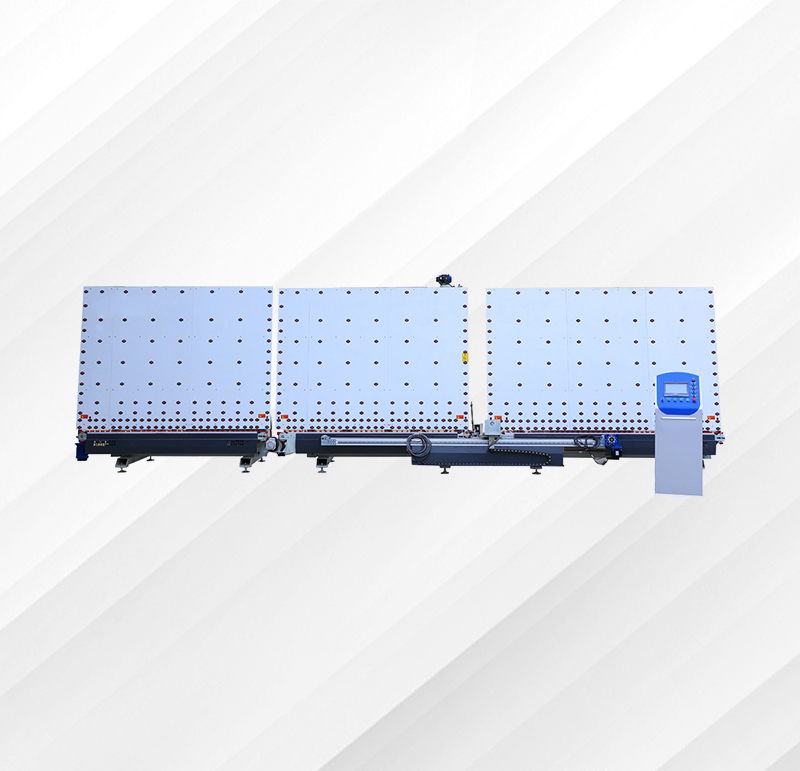

中空玻璃生產線的性能特點

時間:2025-08-23 來源:http://www.shanggu88.com/ 發布人:昌盛機械

01、性能特點

01. Performance characteristics

01段上片段,最前方有 2/5 傳送輪不工作,防止放玻璃時劃傷工作人員,減少 危險因素,保證安全生產。2以恒志為基,意味著我們在蛇年里,無論面對何種挑戰,都堅守初心,不輕易言棄。革新此時,則要求我們把握當下,積極求變。

In the segment above 01, 2/5 of the conveyor wheels at the front are not working to prevent scratching of workers when placing glass, reduce risk factors, and ensure safe production. Based on perseverance, it means that in the Year of the Snake, no matter what challenges we face, we will stick to our original intention and not easily give up. At this moment of reform, it requires us to grasp the present and actively seek change.

02 段清洗段整體材質為 304 不銹鋼,所有軸承底座 304 不銹鋼。毛刷軸承為自動調心軸承,使 用壽命長,精度高。三對毛刷一道擠水輥,雙刀清洗;采用三刷三淋,保證最佳清洗效果,清洗段全部采用優質不 銹鋼,與水接觸部分采用不銹鋼或鋁,水箱配有恒溫水加熱裝置,并配有過濾系統。

The overall material of the cleaning section in section 02 is 304 stainless steel, and all bearing bases are made of 304 stainless steel. The brush bearing is an automatic self-aligning bearing with long service life and high precision. Three pairs of brushes, one squeeze roller, dual blade cleaning; Adopting three brushes and three showers to ensure the best cleaning effect, all cleaning sections are made of high-quality stainless steel, and the parts in contact with water are made of stainless steel or aluminum. The water tank is equipped with a constant temperature water heating device and a filtration system.

02 清洗段采用特殊防護,三對毛刷全部采用軟質高溫絲,鍍膜玻璃膜表面不被破壞,對 于普通玻璃的防霉粉起到洗刷干凈又不會傷害 LOW-E 玻璃的膜層。三組毛刷動力為三組 電機帶動,連接方式為皮帶傳送,當毛刷被外力卡阻時不易憋燒電機。雙風刀模式風干速度更快。風機處加有風門,當清洗機傳送停止時,風門自動關閉,這 樣玻璃停在風刀處時,不會出現因長時間吹熱風形成的風痕。

The 02 cleaning section adopts special protection, and all three pairs of brushes use soft high-temperature silk. The surface of the coated glass film is not damaged, and the anti mold powder for ordinary glass can be washed clean without damaging the film layer of LOW-E glass. The power of the three sets of brushes is driven by three sets of motors, and the connection method is belt transmission. When the brushes are blocked by external forces, it is not easy to burn the motors. The dual air knife mode has a faster air drying speed. There is a damper installed at the fan, which automatically closes when the cleaning machine stops conveying. This way, when the glass stops at the blade, there will be no wind marks caused by prolonged hot air blowing.

03 段傳送部分為兩個傳送電機,可自動識別大小玻璃,小玻璃時可多存放一塊玻璃,從 而提高工作效率。04 段外觀為鋁型材拼接而成,外觀比較美觀,且玻璃背面未清洗干凈時方便再次清理。 檢查燈管使用LED 檢查燈管。04 段鋁框定位為彈簧定位裝置, 自動適用不同厚度玻璃。

The 03 section of the conveyor consists of two conveyor motors that can automatically identify the size of glass. When the glass is small, an additional piece can be stored to improve work efficiency. The appearance of section 04 is made of aluminum profiles spliced together, which is quite beautiful, and it is convenient to clean again when the back of the glass is not cleaned thoroughly. Check the lamp tube using LED. The 04 section aluminum frame is positioned as a spring positioning device, which automatically applies to glass of different thicknesses.

04 段側定位橫梁上有急停和取放玻璃旋鈕開關。緊急情況時,此處離人最近,反應最為 迅速。取放玻璃旋鈕開關接通時,默認 04 段尾部有玻璃,這樣可以將 04 段玻璃取下進 行一些必要的處理,且運行程序不會混亂。段板壓壓合精度高:采用液壓/氣壓驅動,運動采用雙向直線導軌,后板面有自動導向 定位功能,充分保證兩個板面平行壓合,根據中空玻璃板面的大小,設有調壓功能,保 壓時間根據玻璃大小可調整。 背靠輪和傳送輪加密,玻璃運行更穩定,對于鋼化玻璃以及小玻璃效果更好。

There are emergency stop and glass retrieval knob switches on the side positioning crossbeam of section 04. In emergency situations, this place is the closest to people and responds the most quickly. When the knob switch for removing and placing glass is turned on, it defaults to having glass at the end of section 04. This allows for the removal of the glass in section 04 for necessary processing and ensures that the program runs smoothly without confusion. High precision of segment plate pressing: driven by hydraulic/pneumatic pressure, the movement adopts bidirectional linear guide rail, and the rear plate surface has automatic guiding and positioning function, fully ensuring parallel pressing of the two plate surfaces. According to the size of the insulated glass plate surface, it is equipped with pressure adjustment function to ensure stability The pressing time can be adjusted according to the size of the glass. The backrest wheel and conveyor wheel are encrypted, making the glass run more stably, and the effect is better for tempered glass and small glass.

技術參數可加工尺寸300*450mm 2000*3000mm合片方向 板內外自動合片外型尺寸 21500*1500*3150mm功率 25KW清洗速度: 2-12m/min最快工作速度 15-40/min(根據需求,還可提高單片玻璃厚度 T:3-12mm中空玻璃厚度:12-60mm不封膠產 :600-800 片/8 小時 600-800 /8 (1 米長 正常型玻璃.)輸入電壓 : 3p 380V 50HZ壓縮空氣 : 0.6-0.8Mpa,0.8m/min水供應 : 循環水,0.5 噸/天,電導率≤50 μs 0.5t/ ≤ 50 μ s.環境溫度 : 10℃-30℃ ,相對空氣濕度 :≤75%,總重量: 約 2500kg

Can the technical parameters process dimensions of 300 * 450mm 2000 * 3000mm lamination direction What are the external dimensions of the automatic lamination inside and outside the board 21500 * 1500 * 3150mm power 25KW cleaning speed: The maximum working speed is between 2-12m/min and 15-40/min (can be increased according to requirements) Single glass thickness T: 3-12mm Hollow glass thickness: 12-60mm Non sealed production: 600-800 pieces/8 hours 600-800 /8 (1 meter long normal glass.) Input voltage: 3p 380V 50HZ compressed air: 0.6-0.8Mpa,0.8m /Min water supply: Circulating water, 0.5 tons/day, conductivity ≤ 50 μ s 0.5t/≤ 50 μ s. Environmental temperature: 10℃-30℃ , Relative air humidity: ≤ 75%, total weight: approximately 2500kg

本文由 中空玻璃生產線 友情奉獻.更多有關的知識請點擊 http://www.shanggu88.com/ 真誠的態度.為您提供為全面的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from the insulating glass production line For more related knowledge, please click http://www.shanggu88.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

- 中空玻璃生產線:一條中空線至少需要幾個人? 2025/08/23

- 中空玻璃生產線的性能特點 2025/08/23

- 中空玻璃生產線安裝操作要注意什么? 2025/08/17

- 中空玻璃填充氬氣的作用 2025/08/16

- 膠條式和鋁條式中空玻璃的組裝區別 2025/08/12

- 玻璃清洗機使用過程中常見問題、注意事項及維護保養相關知識 2025/08/09

- 中空玻璃設備清洗機的維護保養工作有哪些 2025/08/09

- 中空玻璃的基本制造工藝流程是什么? 2025/08/01

- 雙組份打膠機詳解:從設計到使用維護 2025/07/30

- 雙組份打膠機:應用領域與核心優勢 2025/07/28

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us