中空玻璃的充氣過程!

時間:2019-08-07 來源:http://www.shanggu88.com/ 發布人:昌盛機械

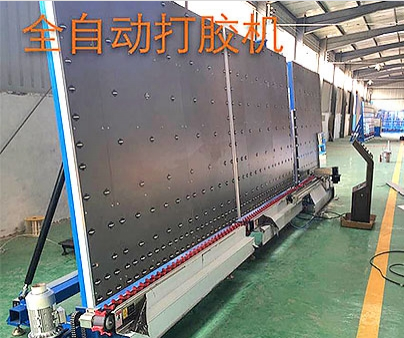

中空玻璃的生產過程中非常重要的就是密封環節了,除此之外還有一個同樣重要而且在操作系數上來說也是更加困難。中空玻璃的賣點就在于隔音隔熱、保溫等一系列優良性能,這些性能靠的基本就是中間的充氣、之后的密封,這兩步驟決定了中空玻璃質量、性能的好壞。今天雙組份打膠機的小編就給大家說說關于中空玻璃的生產條件與組裝要求。

Sealing is very important in the production of hollow glass. Besides, there is an equally important and more difficult operation factor. The selling point of hollow glass lies in a series of excellent performances, such as sound insulation, heat insulation and so on. These performances depend on the gas filling in the middle and sealing afterwards. These two steps determine the quality and performance of hollow glass. Today, the small edition of the two-component gluer will tell you about the production conditions and assembly requirements of hollow glass.

中空玻璃的原理與充氣生產過程控制:

Principle of hollow glass and control of aeration process:

中空玻璃中間夾層是要充進惰性氣體,惰性氣體不容易與外界發生反應,所以這才能讓中空玻璃具備隔音、隔熱等優良性能。在中空玻璃中的惰性氣體多用氬氣,但是氬氣是一種無色無味的氣體,且其充氣濃度不易測量。那如何測量,充氣中空玻璃呢。

Interlayer of hollow glass is filled with inert gas, which is not easy to react with the outside world, so it can make hollow glass have sound insulation, heat insulation and other excellent properties. Argon is often used as inert gas in hollow glass, but argon is a colorless odorless gas, and its aeration concentration is difficult to measure. So how to measure it? Inflatable hollow glass.

充氣中空玻璃的生產過程控制概念是,為確保充氣中空玻璃生產過程處于受控狀態,對影響充氣濃度質量的生產過程所采取的作業技術和生產過程的分析、診斷和實時監控。它的作用在于對生產過程的質量控制進行系統安排,對直接或間接影響過程質量的因素進行重點控制并制定實施控制計劃,確保過程質量。

The concept of production process control of pneumatic hollow glass is to ensure that the production process of pneumatic hollow glass is in a controlled state, and to analyze, diagnose and real-time monitor the operation technology and production process that affect the quality of pneumatic concentration. Its function is to arrange the quality control of production process systematically, to control the factors that directly or indirectly affect the quality of production process, and to formulate and implement control plans to ensure the quality of production process.

中空玻璃的組裝要求:

Assembly requirements for hollow glass:

對環境的要求:溫度也應在10-30度之間;2、相對濕度的要求:此種中空玻璃對相對濕度的要求稍低一些,正常情況即可。但應注意的是,干燥劑應選擇正規廠家的合格產品,以保證干燥劑的有效使用。干燥劑開封后很好于二十四小時之內用完,因為聚硫膠的透氣性較大,密封性差,因此要采用雙道密封。用丁基膠作為一道密封,起到陰隔氣體的作用。用聚硫膠作為第二道密封,主要作用是粘結作用,其次才是隔氣作用。實踐證明,單產密封的中空玻璃壽命只有5年左右,而雙道密封的中空玻璃壽命可長達20年甚至40年以上

Environmental requirements: temperature should also be between 10 - 30 degrees; 2. Relative humidity requirements: this kind of hollow glass relative humidity requirements are slightly lower, normal conditions can be. However, it should be noted that driers should select qualified products from regular manufacturers to ensure the effective use of driers. The desiccant is better to be used up within 24 hours after opening, because polysulfide rubber has a large air permeability and poor sealing, so double-channel sealing should be adopted. Butyl rubber is used as a seal to isolate gas. Using polysulfide glue as the second seal, the main function is bonding, followed by gas insulation. Practice has proved that the service life of single-product sealed hollow glass is only about 5 years, while that of double-channel sealed hollow glass can be as long as 20 years or even more.

今天給大家介紹的精彩內容到這里就結束了,小編在這里十分感謝大家的閱讀,如果大家想要了解更多的相關咨詢,可以把我們的網址:http://www.shanggu88.com添加到收藏,或者搜索關鍵詞:雙組份打膠機,也可以找到我們。

Today's wonderful content for you is over. The edition here is very grateful for your reading. If you want to know more about the relevant consultation, you can add our website: http://www.shanggu88.com to the collection, or search keywords: two-component glue machine, you can also find us.

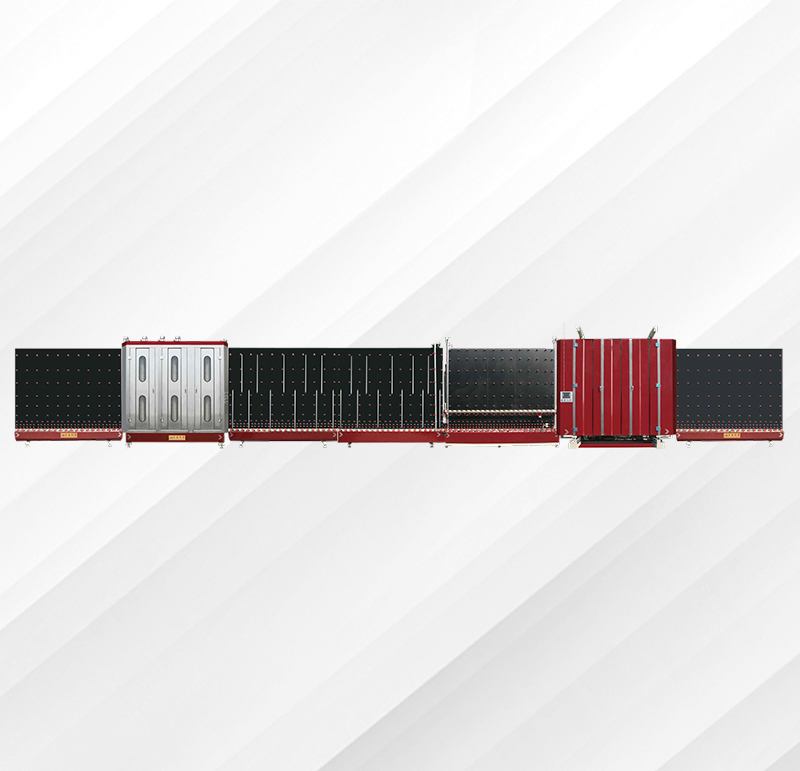

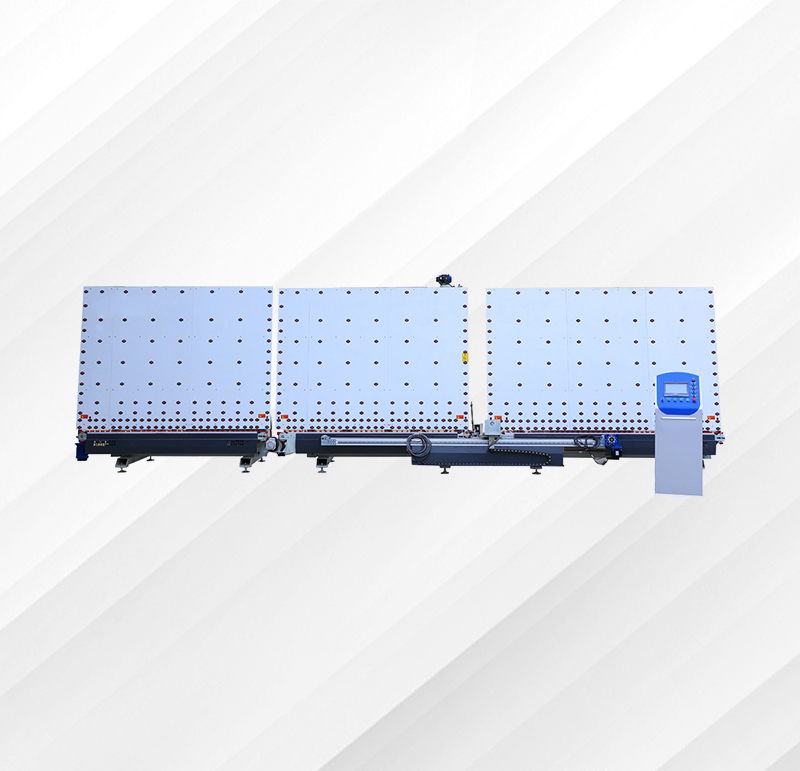

- 中空玻璃加工必備8大設備詳解 2025/05/19

- 全自動鋁條折彎機在工作中有什么優勢? 2025/05/16

- 全自動丁基膠涂布機在工業領域做出來什么優化? 2025/05/14

- 智能升級!全自動封膠線設備實現高精度、高效率密封作業 2025/05/12

- 雙組份打膠機定制流程是什么樣的? 2025/05/09

- 中空玻璃丁基膠涂布機在運行的過程中可能會出現的問題? 2025/05/07

- 全自動鋁條折彎機先進的技術有什么? 2025/05/06

- 雙組份打膠機怎么操作? 2025/05/04

- 帶你了解全自動丁基膠涂布機有哪些優勢 2025/05/03

- 涂布機的工作原理、磨損原因及修復方法 2025/04/27

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us